- Allow the test, specimen, buffer and/or controls to reach room temperature (15-30 °C) prior to testing.

- Remove the test cassette from the sealed pouch and use it as soon as possible.

- Place the Cassette on a clean and level surface.

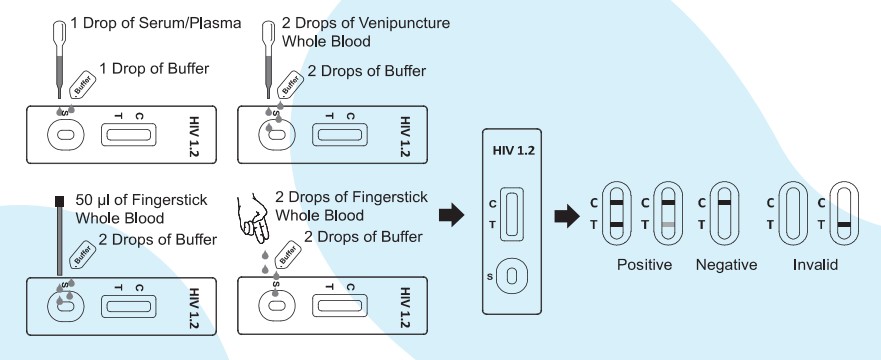

For Serum or Plasma specimen:

- Hold the dropper vertically and transfer 1 drop of serum or plasma (approximately 25 µL) to the specimen well (S), then add 1 drop of buffer (approximately 40 µL), and start the timer, see illustration below.

For Venipuncture Whole Blood specimen:

- Hold the dropper vertically and transfer 2 drops of whole blood (approximately 50 µL) to the specimen well (S), then add 2 drops of buffer (approximately 80 µL), and start the timer. See illustration below.

For Fingerstick Whole Blood specimen:

- To use a capillary tube: Fill the capillary tube and transfer approximately 50μL of fingerstick whole blood specimen to the specimen well (S) of test Cassette, then add 2 drops of buffer (approximately 80 µL) and start the timer. See illustration below. •

To use hanging drops:

- Allow 2 hanging drops of fingerstick whole blood specimen (approximately 50 µL) to fall into the specimen well (S) of test Cassette, then add 2 drops of buffer (approximately 80 µL) and start the timer. See illustration below.

Wait for the colored line(s) to appear. Read results at 10 minutes. Do not interpret the result after 20 minutes.

Note: It is suggested not to use the vial buffer beyond 6 months after opening the vial.

Interpretation of result

POSITIVE:

- Two colored lines appear. One colored line should be in the control line region (C) and another colored line should be in the test line region (T).

*NOTE: The intensity of the color in the test line region (T) will vary depending on the concentration of HIV antibodies present in the specimen. Therefore, any shade of color in the test line region (T) should be considered positive.

NEGATIVE:

- One colored line appears in the control line region (C) . No line appears in the test line region (T).

INVALID:

- Control line fails to appear. Insufficient specimen volume or incorrect procedural techniques are the most likely reasons for control line failure. Review the procedure and repeat the test with a new test. If the problem persists, discontinue usingthe test Cassette immediately and contact your local distributor.